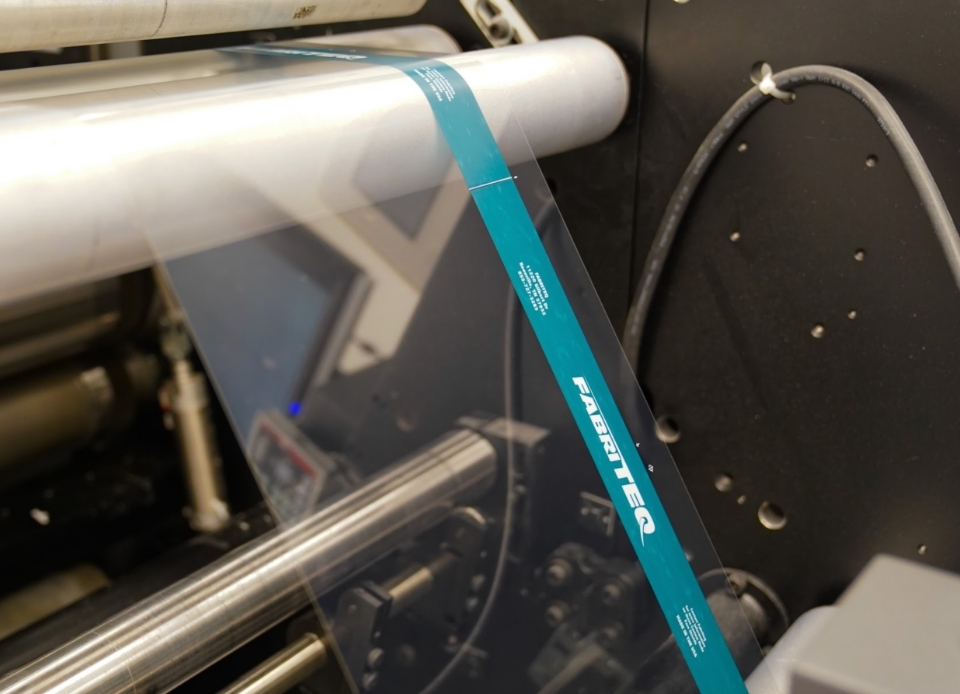

Medical Device Converting by specialists who understand the industry

Medical device converting is our specialty. FabriTEQ engineers can take your medical device design from the back of the envelope to final product launch, designing and producing your medical device in an FDA-compliant environment.

Our specialized equipment supports:

- Rotary Die Cutting

- Laminating

- Island Placement

- Slitting and rewinding

- Heat Sealing

- Perforating

- Embossing

- Metal-to-metal cutting

- In-line slitting

- Kiss Cutting

- Stacked Dies

Products for medical professionals and over-the-counter consumers

FabriTEQ is a converter of high quality, innovative die cutting for healthcare and commercial applications. Our modern converting equipment can fabricate any shape from flexible substrates to meet your specifications. FabriTEQ processes are designed to grow with demand and scale to meet our customer’s needs.

- Die-cut absorbent pads, breathable poly films, woven and non-woven materials

- Adhesive and non-adhesive applications

- Simple to complex geometric shapes

- Adhesive tapes and strips

Our supplied materials include foils, foams, woven and non-woven materials, transparent and unsupported films, skin-contact adhesives, and pressure-sensitive substrates.

Medical Devices

FabriTEQ is a converter and leader in high-quality, innovative die-cutting for medical and wound care products. We offer a wide variety of custom substrates, adhesives, and materials that can be combined to meet a variety of needs:

- Skin-contact wearables, such as body-worn patches and replaceable skin patches

- Sterile and non-sterile skin-contact medical devices

- Sterile-barrier packaging for Ethylene Oxide and Gamma sterilization

- Kit Lidding and Packing services (sterile and non-sterile)

- Medical-grade adhesives, laminates, and tape solutions

- Advanced wound care dressings for moderate to highly-exuding wounds

- Foam and Alginate dressings

- Transparent films and frames

- Wearable devices and single-use consumer care items

Cost, efficiency, and quality balanced for your project needs

A healthcare company that supplies products to clinics and hospitals around the world wanted to move their offshore manufacturing back to the USA. The new US- based processes had to compete with inexpensive manufacturing in China while remaining compliant with existing specifications, cost-containment requirements, and medical reimbursement programs in several countries. FabriTEQ engineers designed new manufacturing processes with negligible cost differences, and helped the client provide a USA-sourced product that complies with medical reimbursement programs around the world.

Our highly trained and experienced engineers draw on decades of collective experience to recommend the right combination of materials, processes, and packaging needed to create your product within specifications. We look at everything from materials to shipping and storage requirements, and help you find the right balance of cost, efficiency, and quality for your project.

Market-winning custom solutions for complex products

A top European medical device company had a unique dressing design that they wanted to bring to market, but production would involve complex processes and they had been quoted a high manufacturing cost. The firm approached FabriTEQ, seeking simpler alternatives that would produce the same high-quality product. We met with the firm’s experts and discussed their needs in detail, to be certain we understood how the product would be marketed, packaged, and used. Using this detailed background, FabriTEQ designed critical feature converting dies and used CNC controlled converting to drastically reduce costs and increase speed-to-market for this project.

The quality is always excellent

We ask for a lot at times and Fabriteq always seems to come through, from the most basic requests to the more complicated changes. Product has been very consistent, and the quality is always excellent.

V.B. Catheter Securement Medical Device company

Get in touch to begin bringing your medical device to market

Call 865-622-4540 or email sales@fabriTEQ.com now!